Difference between revisions of "ExamplesCemented/pt-br"

(Created page with "{{Screenshot|NovoPrjIcon.png}}") |

(Created page with "Para obter informações detalhadas sobre como definir um projeto, visite a página específica: Crie um Novo Projeto.") |

||

| Line 30: | Line 30: | ||

{{Screenshot|NovoPrjIcon.png}} | {{Screenshot|NovoPrjIcon.png}} | ||

| − | + | Para obter informações detalhadas sobre como definir um projeto, visite a página específica: | |

| + | [[NewPrj|Crie um Novo Projeto]]. | ||

Here is the definition of our demo project: | Here is the definition of our demo project: | ||

Revision as of 09:34, 29 June 2017

Nesta página será seguido e explicado o Assistente para escanear 2 modelos em oclusão com 3 munhões (2 superiores e 1 inferior).

Contents

Definição do projeto a partir de Exocad

Para criar este projeto no Exocad, clique no ícone DentalDB na sua área de trabalho. O gerente do projeto será aberto.

Preencha as informações do projeto, o tipo de restauração que precisa ser projetada e os parâmetros extras. Para este tipo de projeto, certifique-se de que o 'Modo Scan esteja definido em 'Dois modelos de gesso em oclusão' .

Para obter mais informações sobre como criar projetos no Exocad, visite a página específica no Exocad Wiki!

Aqui está a definição do projeto para o nosso projeto de demonstração:

Uma vez definido o projeto, clique em 'OPT' na seção Ações para iniciar o software de escaneamento.

A primeira coisa que o software de escaneamento mostra é o projeto criado no Exocad, se o projeto estiver corretamente definido, clique no botão Aceitar ![]() .

.

Definição do projeto a partir do ScanWay

Todos os projetos também podem ser definidos no software de escaneamento, independentemente do CAD que mais tarde será usado para projetar.

Inicie o software de digitalização clicando duas vezes no ícone do ScanWay na sua área de trabalho. A Página de boas-vindas será aberta; Para criar o projeto, clique no primeiro ícone.

Para obter informações detalhadas sobre como definir um projeto, visite a página específica: Crie um Novo Projeto.

Here is the definition of our demo project:

Both the project definitions described lead to the same wizard, which will be now followed step by step.

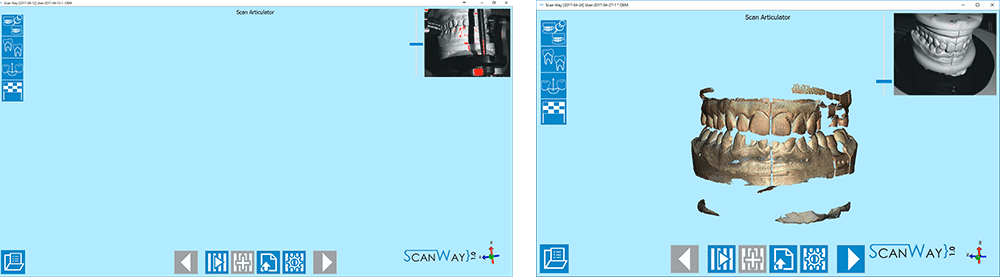

Step 1: Articulator Scanning

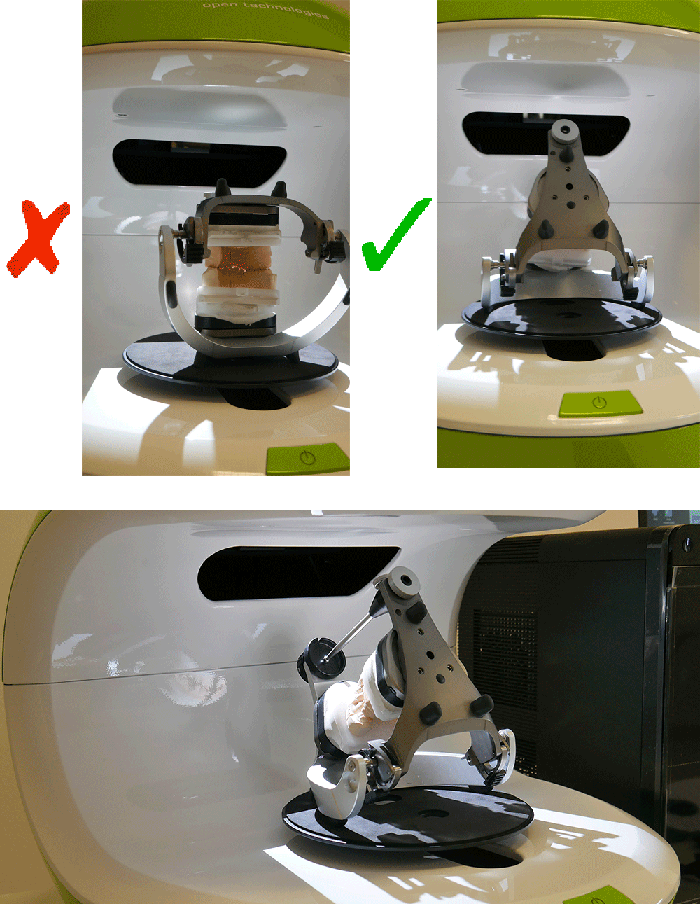

The first step of any project that has been set to have both jaws, is the Articulator Scan.

For Articulator scan it is not necessarily meant that an Articulator needs to be scanned; the required scan is the acquisition of the occlusion either using the articulator on its specific support or putting the two models in occlusion on the model holder.

If the user needs to scan an articulator, we suggest to tilt it backwards, to be able to get as much information as possible. This is just a suggestion as not all articulators can be tilted.

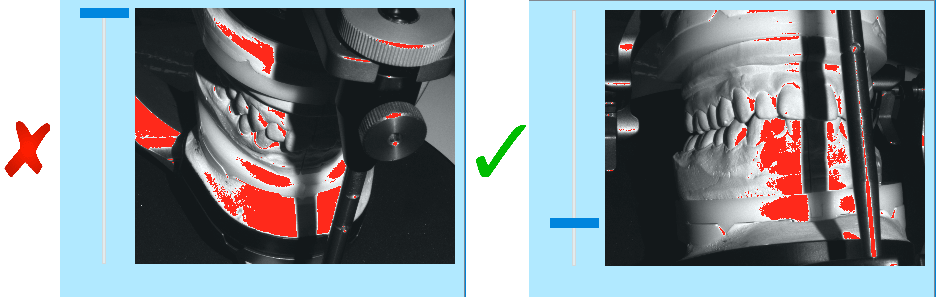

In the live view of the scanning interface you can actually see that if the articulator is standing straight it will be difficult to acquire the occlusion properly.

On the other hand, as previously mentioned, it is also possible to scan the two models in occlusion on the normal model holder held together with rubber bands or wax if necessary.

Once the objects have been placed in the scanner (either the articulator or the models one on top of the other), the scan can be started with the Scan Button![]() . Once the scan is finished the result will be shown.

. Once the scan is finished the result will be shown.

For further information on the other available functions check the Scan Interface page.

Click ![]() to access the second step of the wizard.

to access the second step of the wizard.

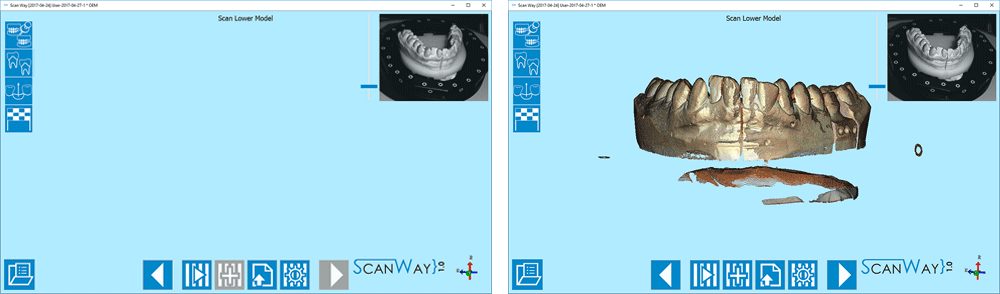

Step 2: Lower Model

The second step of any project that has been set to have both jaws, is the Lower Model Scan. All steps, except for the articulator one, include two sub-steps: the actual scan and the edit of the acquired image.

Scan Step

Place the lower model on the model holder and click the Scan Button![]() . Once the scan is finished the result will be shown.

. Once the scan is finished the result will be shown.

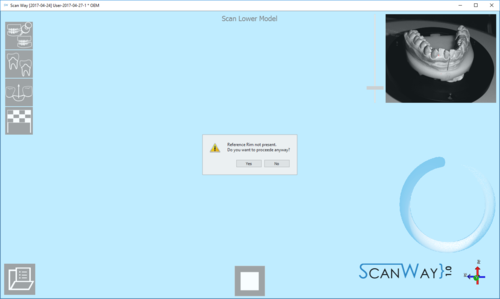

This scan has been performed with the Reference Rim. Everytime the user launches a scan for models, dies or markers, if the software recognises that the reference rim has not been used the following message shows.

The user can therefore decide whether to cancel the scan, put the reference rim on the model holder and start a new scan, or to scan without using the reference rim. For information on the reference rim visit the Accessories page.

Click ![]() to access the second part of the Lower model step.

to access the second part of the Lower model step.

Edit Step

This step allows to edit the aquired image; for detailed information on all the available options in this step visit the Edit Tools page.

The image at this step can be both edited or trimmed. At this stage it is actually important not to edit too much the image or cutting big chunks of information, since it would make it more difficult for the software to calculate the automatic alignment of the object to its reference.

The edit of the image can be carried out using the selection tools.

On the other hand, trimming gets very easy when the cut base tool is used.

When you are satisfied with the result click ![]() to access the next wizard step.

to access the next wizard step.

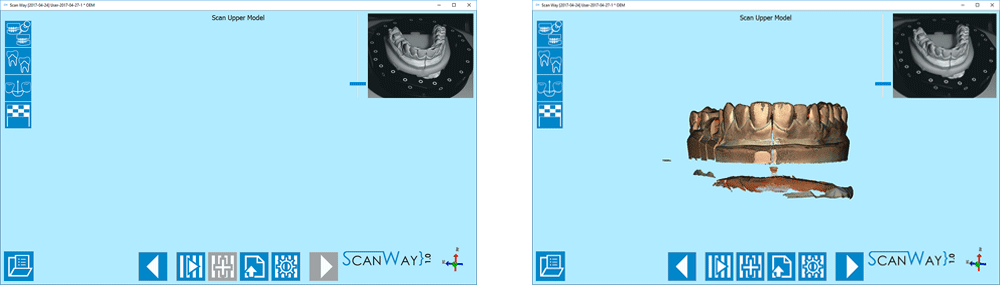

Step 3: Upper Model

The upper model Scan, like the lower model, requires the user to undergo two steps.

Scan Step

Place the upper model on the model holder and click the Scan Button![]() . Once the scan is finished the result will be shown.

. Once the scan is finished the result will be shown.

As before, if the reference rim is not placed on the model holder, the software will show the relevant message.

Click ![]() to access the edit step for the Upper model.

to access the edit step for the Upper model.

Edit Step

The upper model can still be edited as shown for the lower model. This time, we will edit the image using a different selection tool.

When you are satisfied with the result click ![]() to access the next wizard step.

to access the next wizard step.

Save and Align

Immediately after having pushed the ![]() button, the software saves and tries to align automatically the scanned items to their reference.

button, the software saves and tries to align automatically the scanned items to their reference.

To learn more on the automatic alignment and the manual procedure visit our Alignment Interface page.

Step 4: Dies Scan

The steps necessary to successfully scan the dies vary depending on the scanning method that the user chooses to apply: the use of the multidie plate or the custom set-up.

With Multidie

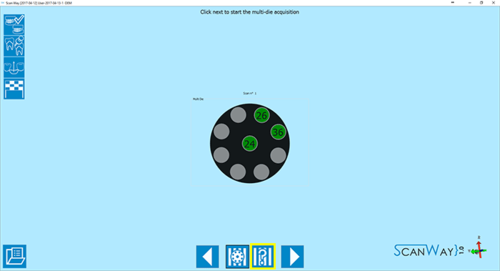

This method is applied by default by the software. It implies that the user will put the dies on the multidie plate in the position shown by the software, which will make each die immediately recognisable and cut the steps of the wizard.

- Definition

- As mentioned, the position of the dies in the multidie plate is pre-established by the software.

The multidie order is based on the Universal tooth numbering, starting from the last element of the first quadrant and following in a clock-wise order. Therefore the die that needs to be placed in the central element will always be the one closest to the last element of the first quadrant.

If there are more than 9 dies, a second definition step will be shown.

Click ![]() to access the multidie scan step.

to access the multidie scan step.

- Scan

- The multidie scan interface is similar to the other steps we just explained, except for the multidie reference that is kept as a reminder on the right side of the window, under the live view.

To proceed click the Scan Button . Once the scan is finished the result will be shown.

. Once the scan is finished the result will be shown.

Click ![]() to access the edit step for the multidie scan.

to access the edit step for the multidie scan.

- Edit

- The edit step offers the same tools we saw in previous steps. In this case, more than one tool may need to be applied.

When you are satisfied with the result click ![]() to access the next wizard step.

to access the next wizard step.

- Alignment

- After being edited the dies get aligned to their references. The result is then showed on the monitor. To learn how to change, fix or redo the alignment check the Alignment Interface page.

Custom Set-Up (Without Multidie)

The user can also decide to scan the dies in a custom order, for instance if he needs to scan the dies on the model base. To access the custom set- up definition, click on the ![]() icon when the software presents the multidie definition.

icon when the software presents the multidie definition.

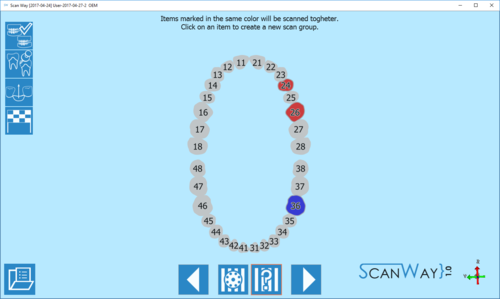

- Definition

- The software proposes by default a unique scan group which means that, if not defined otherwise, the software will ask the user to scan all the stumps together. In this case I have created a second scan group, to divide the scan of the upper dies from the scan of the lower dies. Click

to access the scan steps.

to access the scan steps.

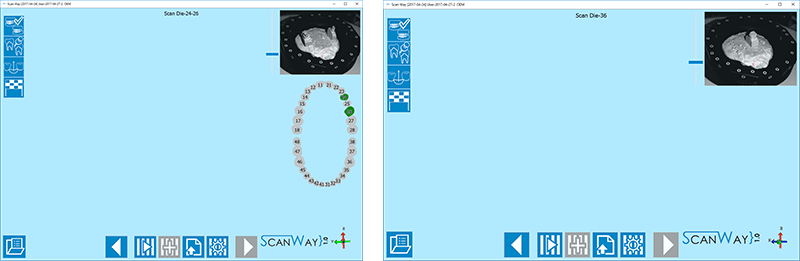

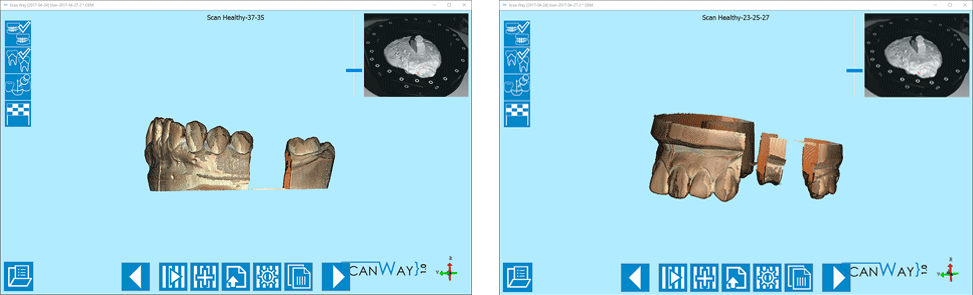

- Scan

- Depending on the number of scan groups created, the software will propose one or more scanning steps.

First, the software requires the user to insert the dies in the scanner and acquire the items of the first group.

As a reminder, it marks the items to be scanned together on the right of the window, under the live view.

Then it will ask the user to insert the item selected for the second group. Since the second scan is an individual die, there will be no reminder on the right. Click ![]() to continue.

to continue.

- Dies Identification

- When a scan group has more than one item, the user will be asked to separate each die from the others to correctly identify it.

This step occurs in between the scanning steps. To learn more on the identification of the dies visit the Scan Interface page. Click to continue.

to continue.

- Edit

- If the scan group is formed by one individual die, there will be no identification step. Instead, the edit step will be presented. Click

to continue.

to continue.

- Alignment

- After being edited or identified the dies get aligned to their references. The result is then showed on the monitor. To learn how to change, fix or redo the alignment check the Alignment Interface page.

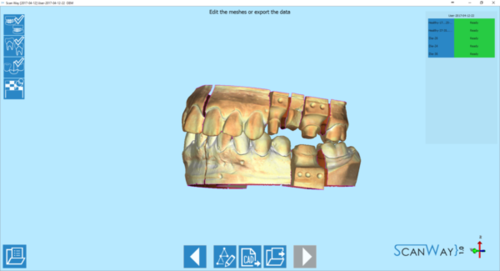

Step 5: Healthy and Pontics

At this stage the project has been scanned, unless the user wants to rescan the healthy and pontics. This step is infact a result of the scan of the scanned reference model, trimmed to exclude the parts that have been scanned individually (in this case, the dies). It sometimes happens that in the first model scan, the contact points on the healthy are not correctly recognised, which would require the user to rescan the model. Otherwise, just click ![]() to continue.

to continue.

The software will then propose a further edit step to allow the user to modify the healthy image. Proceed in the edit step as previously explained.

Step 6: Mesh Generation and Export

At this point the software immediately starts mesh generation. The meshes can be edited and exported individually or as a unique image. To learn more about mesh editing visit our Mesh Tools page.

Click on the Export Button ![]() to export to CAD.

to export to CAD.

If the project has been started from Exocad, the CAD will automatically open and the design can be started immediately. Otherwise the software will ask the user how to export the file.